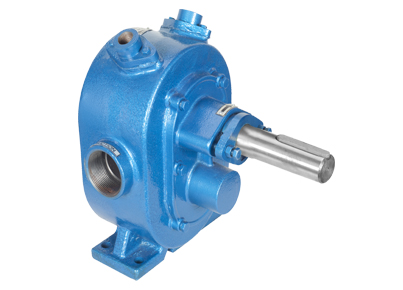

FLUID TECH SYSTEMS commenced its business operation in 1993, under the able guidance of great visionary leader Mr. Mansukh Patel. What started off as a modest production capacity plant is today is one of the largest producers of Rotary Gear Pumps in India.

Contact Info

73, Tribhuvan Industrial Estate, Opp. Water Tank Nr. Kathwada GIDC, Road No. 11, Ahmedabad-382 430, (GUJARAT) (INDIA)